FOR SALE

“Sea Spirit” – 2009 Sea Spirit Passagemaker 60

$1.495m

Our 2009 Sea Spirit Passagemaker 60 is now for sale for $1.495m, as we have recently bought a larger boat.

For details, please contact Judy Waldman at (954) 895-8844 or send her email.

What we like and dislike about Sea Spirit

Before purchasing our Sea Spirit Passagemaker 60 yacht, we looked at a lot of boats, both in person and on sites like YachtWorld. While one could talk forever about one brand of boat versus another, this page will simply talk about our boat, and what we like and dislike about it. I’ll try and keep the discussion about technical and practical issues, because it’s pretty pointless to talk comparatively about aesthetics. It suffices to say that we obviously like the look of Sea Spirit, but recognize that everyone will have their own tastes in this area.

Hull shape – full displacement

Sea Spirit’s hull is full displacement, meaning that it never even attempts to rise out of the water in order to obtain higher speeds. In return for this concession, the hull provides an exceptionally gracious ride across the rough water that will inevitably be found somewhere along a passage. Indeed, in those places, faster boats must slow down to avoid damaging the boat or crew, and at the reduced speeds, the displacement hull will provide a far better ride. Although people often talk about how rugged their boats are, the reality seems to be that it is the ruggedness of the crew that determines whether a passage is a good one or not. By providing the smoothest possible ride, Sea Spirit’s full displacement hull ensures that we will be able to make passage when many other boat crews simply will choose not to.

Hull shape – efficiency

Sea Spirit’s hull is amazingly slippery, meaning it seems to present a bare minimum of resistance to the water it pushes aside. I attribute this to many factors, but all of them derive from the experience of Sparkman & Stephens, who designed the hull. S&S are best known for their racing sailboat designs, including winners of many America’s Cup, Fastnet, and Sydney to Hobart races. Ironically, they also designed the “Duck Boat” amphibious vehicles, which don’t win any races, but which contributed to many victories in WWII, and for which Rod Stephens Jr. won the US’s highest honor, the Medal of Freedom. The bottom line is that these folks have a long history of designing hulls to meet specific needs. In the case of Sea Spirit, those needs are for great seakeeping combined with great economy, while maintaining enough interior room to house a family. Two factors in particular struck me as pertinent to the hull’s efficiency. First is the bulbous bow, pictured below. Second is the slightly concave area underneath the swim platform. In addition to the general shape of the hull, these factors add to its efficiency. As evidence of this, our boat cruises at 7 knots on about 2 gph, 9 knots on 5.5gph, and can reach 11 knots in smooth water at wide open throttle (16gph). This not only saves on operational costs, but gives the boat a tremendous range. In turn, that range leads to more flexibility in where fuel is taken aboard, which can save on both time and money.

Speed

Mmm. Didn’t I just finish saying that the full displacement hull isn’t good for speed? True. However, when looking at boats, we came across several that were about the same length as our Sea Spirit, but which traveled much slower. This is due to one of three reasons. One reason is that sometimes the engine paired with the boat was insufficient to push the boat at its hull speed, generally defined as 1.34x the length at the water line. Another perhaps similar reason is that sometimes we came across a similar length boat, but much beamier (wider). While this is not in and of itself a bad thing, wider boats have a tougher time going fast. To be honest though, I would love to have our boat in something a couple feet wider, even if it meant a bigger engine was needed to push it to its hull’s speed limits. At 17′ 2″ wide, our Sea Spirit is plenty wide enough, but on the other hand, more interior room is never a bad thing! The third reason we found so many other boats that did not go as fast is that their hulls simply weren’t as slippery, or didn’t have the bulbous bow that supposedly pushes the bow wave away from the boat, allowing it to go faster. Here’s a picture from our sea trial of hull #3 on Lake Union, showing 9 knots at 5.8GPH. Our engine is slightly different, but the numbers are close.

Daylight range

This is related to speed. It has always struck me as a good idea to arrive at the evening’s anchorage or marina with plenty of daylight left. The faster the boat goes, the further one can travel in a single daylight run, without having to worry about running overnight, or arriving in the dark. Our boat loafs along at 9 knots at 5.5 gph, and can be pushed to 11 knots at 16 gph in flat water. This means that in a 12 hour tropical day, we can start at dawn, go 108NM on a rough day, or as much as 132NM on a smooth day, and arrive at dusk. In the Pacific Northwest, where summer days are more like 16 hours long, we can go from 144NM on a rough day, and 176NM on a smooth day, all without traveling in the dark. This is both a significant safety asset and also a significant comfort asset. Do we intend to travel that much each day? Of course not. But there will be days where this capability is extremely helpful. If our boat could only make 7 knots, we would still be very happy, but would not be able to traverse as much coastline between sunrise and sunset. It is also fair to say that at 20 knots, we’d to that much further. But perhaps not, if the weather was rough, because the trip would become so uncomfortable that we would elect not to proceed at that speed. We ended up feeling that being able to do at least 10 knots gave the boat a clear advantage.

Ability to run

Ok, this is the last segment on speed, I promise. Linda and Steve Dashew, boat makers and sailers extraordinaire, have me sold on the safety virtues of speed. Their argument goes as follows. When making a passage, one waits for a weather window, and then proceeds, hoping that the forecasted weather holds. The longer the passage takes to complete, the less accurate the forecast is likely to be. The less time the passage takes, the more likely the forecast is to be right. So, faster is better. Also, when the weather turns out not to be as forecast, the ability to make good headway out of the path of whatever the bad weather brings, is very useful. Once again, more speed equates to more safety.

Keel with fully protected propellor and rudder

Most trawlers have this, and Sea Spirit does too. It is important that the running gear is protected in case of running aground, but also in case of hitting logs, seaweed, cables, and other submerged obstacles. It was important for us to check not only that the running gear was protected, but that the protection was beefy. On Sea Spirit, it is. There are also “kelp cutters” ahead of each hydraulic stabilizer fin, to prevent things from hanging up in the small space between the fins and the hull.

Hull shape that promotes stability without compromising seakindly ride

Some very well respected boats, such as Nordhavns, have fairly rounded hulls that spread the sea’s tipping forces out over time. This causes the boat to roll more, but to take more time doing so, so the rolling is gentler. Some other boats have fairly flat bottoms, which take those forces and apply them very rapidly to the boat. These boats roll less, but quicker, so the rolling is rougher. Sea Spirit takes a middle ground, with a bottom that is somewhat round and somewhat flat (but not so flat as to become semi-displacement). This gives an acceptable ride without the need for stabilizers, and a superb ride with stabilizers. All Sea Spirits come with stabilizers, but I would classify their use as optional, whereas on truly round-bottom boats, some form of stabilization is more or less mandatory.

High freeboard, solid coamings

Freeboard is the distance from the waterline to the part of the hull over which water would have to come to enter the boat. Sea Spirit has 8′ 9″ of freeboard at the bow, and 6′ 8″ at the stern, all of which helps keep the ocean on the outside. Since we have children, one thing we particularly liked was that the boat’s coamings (the part of the hull that rises vertically above the deck, and that has the teak hand rails on top) extended all the way to the bow. On some other trawlers, anyone standing on the foredeck is protected only by stainless steel lifelines (cables), and can get very wet or be swept away. On Sea Spirit, anyone on the foredeck is nicely protected. In fairness, the reason some other trawlers use the lifeline approach is because their foredeck is pushed very high, in order to maximize room in the forward cabin underneath it. Some may prefer that approach, while others prefer having a nice “recreationally useable” foredeck, which is what Sea Spirit provides. Actually, one of my favorite things to do on Sea Spirit is to sit right at the bow on the teak seat that is built in there, and look over the front of the boat, pretty much completely protected from the wind.

Huge freeing ports, hawse holes, and cleats

In the event that water comes over the coamings, an important question is: how will it exit the boat. In Sea Spirit’s case, there are huge “freeing ports” at the bottom of the coamings, so that any water that comes aboard can quickly drain. Especially since the bow coamings are so high and solid, this is important.

Portuguese bridge

The Portuguese bridge allows you to walk all the way around the front of the wheelhouse while remaining very protected, even from water that might come over the bow. We really fell in love with how Sea Spirit protects both large and small occupants from the wind and ocean.

Anchor

Here is something I don’t like about Sea Spirit. While it looks absolutely wonderful, the boat’s Pool style anchor could be better, in two ways. First, it is not the world’s best anchor in terms of holding the bottom, although it is way better than many other kinds. Indeed, in order to ensure sufficient holding power, Sea Spirit Yachts chose to put an anchor aboard that weighed about 130 lbs. But if I were building a new Sea Spirit from scratch, I would ask for something like a Rocna, CQR, or Ultra anchor. At the same weight, you would get more holding power. Those digging anchors are also supposed to do better in a shifting current, although it is possible that the Pool anchor we have on the boat will be fine. The other thing I don’t like about the anchor setup is that there is only a single anchor. I would prefer to have the ability to store and deploy two anchors from the foredeck. Actually, a more recent Sea Spirit Passagemaker 60 was specified with a double anchor setup, so we know it is possible to do. I would recommend it. Our alternative is to have a Fortress FX-85 anchor as our second anchor, which we store at the stern, and may well deploy from the stern. Because of the high coamings, deploying a heavy anchor from the bow (and later retrieving it) would be a chore. A dual built-in anchor setup would rectify this situation.

Bow and Stern Thrusters

While we’re on the subject of things I don’t like, my particular Sea Spirit Passagemaker 60 has electric bow and stern thrusters. They are actually top of the line for electric thrusters, but I wish they were hydraulic. The issue is that all electric thrusters “time out” after being used for a while. I have actually had this happen to me, and it is not pleasant. A quick call to the manufacturer (Side Power – they make both electric and hydraulic) resulted in some suggestions that I check the brushes and thermal cutout switches. I replaced both recently, so we’ll see whether the situation improves. It’s not that it’s bad, but hydraulic would be better. They can be changed out for hydraulic ones, and I may consider that at some point, but for now I’ll see how the new brushes work out. At any rate, I will say this much about the bow and stern thrusters: They are plenty powerful, and let me do an amazing job of spinning the boat around, even before I really learned how to drive the boat just on the single screw.

Asymmetric deckhouse

The deckhouse is the part of the boat behind the wheelhouse, and is essentially the boat’s kitchen and living room. These days, most boat manufacturers offer either a symmetric or asymmetric deckhouse. In a symmetric set-up, you can walk outside the deckhouse around either the port or starboard sides of the boat, which is superb for docking and undocking. However, it reduces the width available for the living area inside the deckhouse. Many people, including me, think that an asymmetric deckhouse, where one side is pushed all the way to the outside of the boat, eliminating the walk-around on that side, is a good compromise. In nearly all cases, you will be able to dock so that the remaining side is to the dock. But some people are adamant that walk-arounds on both sides must be present, and are willing to forego some interior space in return. We prefer the asymmetric approach, which on our boat means we can walk around the starboard side of the boat, but not the port. Like most boat makers, Sea Spirit Yachts offers both, to suit different tastes.

Day head

Ok, this isn’t really a technical issue, but it is one of the things we love about Sea Spirit. At the front of the salon on the starboard side, on the way to the wheelhouse, is a “day head”. In a house, this would be called a powder room. It is essentially a toilet and sink that are conveniently located between the two main “daytime” areas of the boat — the wheelhouse and the salon. Hardly a necessity, but a nice touch. In the photo below, it’s opposite the kitchen, through the closed door.

Canoe stern

We like the styling of the rounded canoe stern, but could have been just as happy with a square stern boat. However, there are some advantages of the canoe stern. One is that it presents less resistance to following waves than would a square stern. This can be an advantage in avoiding “broaching”, which is where the stern of a boat is pushed sideways by waves overtaking it, and is a very dangerous situation. Sea Spirit’s canoe stern catches less of the energy of this kind of following sea, and as a result is pushed around less. But there is a catch. The catch is that the rounding of the stern unfortunately has to take a little space away from what would otherwise be spaces inside the cockpit of the boat.

Wrap-around swim step

As a result of the rounded stern styling of Sea Spirit, the swim step extends further forward than it would on square-stern boats. This allows us to moor a dinghy around the side of the swim step, while still having lots of swim step “edge” for swimming. And yet the dinghy will not need to be brought around the back in order to step aboard. It is possible to step aboard almost the whole length of the dinghy’s seating areas without moving it. This is only a small advantage, but it is one we like.

Pantographic door in the transom

This looks really cool and “shippy”, but is a nuisance, since it is quite heavy to open and close. It could be powered, but that would add complexity. I’m not sure if there is a better alternative, and it seems a small price to pay, but nonetheless, it is a nuisance. (Sorry – no good photo yet).

Live bait well

In the swim step, Sea Spirit Yachts built a well to hold either live bait, or live fish that have been caught. There are a couple of pumps for keeping it full or empty of seawater, so that the fish will always have fresh oxygen. We’re not big-time fishermen, but my 10 year old thinks this is the sweetest feature on the whole boat.

Teak

Ugh. For some reason, I find the notion of re-finishing teak cap rails every 6 – 12 months very distasteful. My boat, like many others, has teak cap rails. When varnished, they look absolutely fantastic. But like every other teak cap rail in the world, when that varnish starts to give in to the power of the sun (and in the tropics, it’s only 6 – 12 months), it looks terrible. Our solution was to realize the intrinsic beauty of bare teak, so we stripped the varnish off, and went bare. Whether we’ll like this over the long term is an unknown, but we like it a whole lot better right now, and ongoing maintenance is minimal. We also have teak in the cockpit and on the swim step, but those areas are already bare. One great thing about bare teak versus varnished teak: bare teak doesn’t heat up very much in the sun, whereas varnished teak very quickly gets too hot to touch on a sunny day. If I were spec-ing a new boat, I’d go without teak at all on the cap rails (opting for fiberglass with stainless steel handrails), and I would specify one of the “fake” teaks for the swim step, and perhaps for the cockpit too. On Sea Spirit’s teak in the cockpit/swim step, I worry a little about stains from things like fish blood. Time will tell. Stains can always be sanded out, but I’d prefer not to be a slave to the teak. By the way, the wood on the inside of the boat is all teak, and looks wonderful. I think teak is a great wood for indoor use.

Main engine

Sea Spirit’s main engine is a Lugger L1276A2. The L means it is a Lugger. The 1276 means it is a 6 cylinder diesel with 127mm bore. The A means it is after-cooled, and I believe the 2 means this is revision 2 of that particular model of engine. It is a 340HP engine that started life as a John Deere, and then was marinized by Lugger. The marinization includes toughening up many of the parts bolted on to the engine, removing any belted components (other than alternator), modifying the cooling system and exhaust (including installing a thermostatically controlled, liquid-cooled turbocharger).

Sea Spirit Yachts offers other engine choices, but I am very satisfied to have this engine in my boat. One of the best things about it is that it develops its power at very low RPM — 1800. I also like the fact that it all of this power is available within the engine’s continuous rating range. This means that it can run at full power 24 hours per day for its entire life, without wearing out. Indeed, in an industrial setting such as running a generator at a remote facility, this is how the engine (well, the pre-marinized version) is run. While all engines can put out their full rated power, not all can do so continuously. For an offshore boat that might make the run to Hawaii one day, being able to run continuously for days and days is very useful. Having said that, nobody runs to Hawaii at full rated power, so even an intermittently-rated engine would do fine. Perhaps the continuous rating is overplayed, but it’s a nice comfort factor. I would not reject a boat because its engine wasn’t continuously rated, though. I would reject a boat if the engine turned at a very high RPM at cruise power, because doing so changes the character of the noise that the engine produces. At 1300 – 1500 RPM, Sea Spirit’s engine is not only very quiet, but what little noise does escape the engine room is low enough in pitch so as to not be objectionable.

Like all new engines these days, Sea Spirit’s engine is electronically controlled. This allows it to meet emission standards, but also makes “smokey startups” a thing of the past. The engine control unit (ECU) controls the fuel injectors, ensuring that only exactly the right amount of fuel is injected, and at exactly the right time, regardless of the engine’s temperature or workload. This also helps tremendously with efficiency. However, it does mean that if the ECU fails, either due to some sort of internal failure or due to external forces such as lightning, the engine likely won’t run. Sure, there are “limp home” modes on the ECU in case the various sensors fail on the engine, but if the brain fries, the engine will stop. There are many out there who will say “Mmm, I’d prefer to have an entirely mechanical engine — easier to work on too”. I would not reject a boat that had a mechanical engine with no brain, but I believe I would prefer the cleanliness and efficiency of the ECU approach. I don’t currently carry a spare ECU. It may be that this is a mistake, and my mind is not fully made up on the subject.

One cost of having this lovely, continuously rated engine, is that it is quite large. I’ve been aboard one of Sea Spirit’s sister ships, that had a similar level of power available, but from a smaller John Deere engine. I remember how spacious the engine room on that boat felt, but when given the choice of the two engines, I was still very happy to have my large, slow-rotating engine. The JD turned a couple hundred RPM higher than the Lugger, to produce a similar output. the JD was slightly more efficient, though.

Another cost to having a Lugger rather than a John Deere (or Cummins, or some other brand) is that the Lugger engine costs about 50% more to buy, and the parts are more expensive. Whether this is worth it in the long run I don’t know. I do know that many fishing boats in Alaska use Lugger engines and Northern Lights generators (made by the same parent company — Alaska Diesel Electric), even despite the expense. Those guys are not known for wasting money, so my heart says this is the way to go, despite the cost.

As it came from Sea Spirit Yachts, Sea Spirit’s fuel system had a couple of quirks. First of which was that while the company had installed a very high quality fuel polishing system from Racor, it only allowed polishing fuel as the fuel entered the day tank. Thus, there was no way to polish fuel in the main tanks, or even to re-polish the fuel already in the day tank. When fuel sits for a long time in any tank, trouble can pay a visit in the form of sediments, growth, water, and so on. While it is acceptable to only be able to polish (which really just means “filter”) the fuel as it is transferred to the day tank, it is far better to be able to polish it from and back into one of the main tanks. That way, the main tank fuel can be kept clean, preventing the accumulation of trouble in the first place. One hears stories of main tanks whose fuel was thought to be clean, but after being sloshed around in a rough seaway, a lot of guck was churned up. That guck hopefully never makes it to the engine where it can clog up an injector, but it certainly can clog up the filters and starve the engine, right at the time when one doesn’t want to be mucking around changing filters. As I say, it is far better to simply have clean fuel everywhere on the boat, eliminating this problem, or at least discovering the problem at a safe, convenient time.

To remedy the fuel polishing situation, I had to have a new manifold fabricated and installed (above left — yellow handles), and some new fuel plumbing made. Fortunately, this was easy in Ft. Lauderdale, and took only a few days in total. Thank goodness the access inside the engine room is very good. I also had a second fuel polishing pump plumbed and wired in, in parallel to the existing one. This means that a faulty pump won’t stop me from moving fuel around, even against the force of gravity. As a final backup, even if all fuel transfer pumps fail, I can use gravity to transfer fuel into the day tank, from which it will be drawn into the engine by the engine’s own mechanical pump.

Speaking of filters, I think Sea Spirit Yachts chose very well. Everything is Racor, with double paralleled filters on the main engine, so that one can change filters without stopping the engine. You can’t quite see it here, but the dual Racors have a vacuum gauge between them, which helps identify when the filter is beginning to clog. The generator filters don’t have that yet, but they will be installed this week. As you can see from the image below, everything is clean and labeled, avoiding the current trend of placing absolutely all tubing, piping, and wires behind bulkheads. I feel fortunate that Sea Spirit Yachts made access a priority.

Generators

Sea Spirit has two Northern Lights generators, one of which is 20KW and the other is 16KW. Either generator seems to be powerful enough to run everything important on the boat, including air conditioners. Perhaps I will need to run both at once sometime, but I haven’t had to so far. There seem to be two schools of thought about generators. Either they should both be identical, so that spare parts can be shared, or one should be significantly different in capacity from the other, so that you can start the generator that best meets the load demand of the boat. Many people are of the opinion that running a diesel engine at less than 60% (roughly) power is bad for it. However, with these modern, electronically controlled diesels, I’m not sure this is the case any more. My main engine, for example, has no trouble generating the right internal temperatures, even at low power. So, I am not as worried about some people about running a large generator with a small load. Given that, if I were spec-ing out a new boat, I’d order two identical generators, for simplicity. I’m not sure why one of mine is a 16 and one a 20. They both seem to take up the same amount of space, and indeed are both based on the same engine block (the 20 has a longer stroke). The Northern Lights generators are extremely well respected, but other brands such as Kohler are known to be good too. I’m happy with mine. They are very quiet – much quieter than I thought they would be, even inside the engine room.

Both of Sea Spirit’s generators have hydraulic pumps attached to them, to send power to the “get home” engine (described below). Note: It looks like these generators would be hard to service. However, the “sound enclosures” surrounding them come apart very easily, just by undoing 4 clips (no screwdriver required), and so access is actually pretty good.

Hydraulic stabilizers.

The main engine also has a hydraulic pump on it, but for a different purpose — to power the hydraulic stabilizers. I sometimes wonder whether it is better to have one hydraulic system that powers everything, or two (or more) separate ones. I can see plusses and minuses to each. For example, on Sea Spirit, if there’s a loss of pressure in the get-home drive, it doesn’t affect the stabilizers because they are on a separate system. On the other hand, if the main engine stops, the hydraulic pumps on the generators cannot power the stabilizers. It’s a conundrum, probably one with no “absolute right” answer.

Sea Spirit’s stabilizers are from Wesmar, although the manufacturer offers a number of other options. I have no basis for comparison with other systems, but I can say that while the boat is reasonably stable without them turned on, it is very stable with them turned on. The fins are 9 square feet each, which seems about “average” for this length of boat. Some stabilizer systems allow the boat to be stabilized while at anchor, but Sea Spirit’s system does not. As you can see from the picture, the system is both rugged and straightforward.

A word about stabilization. There seem to be three kinds of motion that cause motion sickness: roll, pitch, and heave (which is the vertical up and down motion of the boat as it is lifted and dropped by waves). Of these, roll is the most severe, and this is what stabilizers correct for. However, heave is also a significant component of mal de mer, and stabilizers do nothing for heave.

Exhaust

Here, there were some things that we liked, and some things that we didn’t. Fortunately, without me even asking, the manufacturer chose to address the exhaust system’s shortcomings during the commissioning period. What we liked was that the exhaust for all three engines (main plus two generators) went through air/water separators, releasing the liquid below the water line, and the gas above. This greatly reduces the “percolating” sound that would otherwise occur if both gas and water were released together. What we didn’t like was that the exhaust “mixer” (the place where cooling water is introduced into the hot exhaust stream to greatly cool it), was made of stainless steel. Stainless steel is great until it corrodes over time, and my understanding is that it is never a good choice for below the waterline. While the exhaust is not below the waterline, it is immersed in sea water, and hot seawater at that. The whole exhaust system was upgraded to use far better materials, including the use of Inconel for the mixer. Inconel is FAR more resistant to corrosion. In the generator photo (above), you can see the old exhaust, before the upgrade. Here is a photo after the upgrade. The materials are much better.

Seacocks

All of the seacocks on the boat are bronze, and are made by Perko, and have heavy bronze handles. There are many cheaper brands on the market, but Perko and Groco seem to hold the upper end of the market. There are only a few below-the-water-line seacocks. One is for the main engine, there’s one for each generator, one for the air conditioning, and one for the watermaker. One could quibble that perhaps there should be a sea chest. A sea chest in its simplest form is simply a large hole in the bottom of the boat, with sides that are raised inside the boat so as to be above the water line. Seawater inlets for the boat’s machinery are taken from the sides of this box. The box often has a glass top, so that one can see the condition of the actual inlets from inside the boat. One can supposedly remove the glass top, reach down into the water, and clean the inlets. It’s a really cool idea. I’m sure the box imposes some drag, and of course, it takes up some space inside the engine room. The most interesting version of this that I’ve heard about involves placing the box over top of the propellor. This means that one can reach down and untangle the propellor if it becomes tangled. At any rate, Sea Spirit does not have a sea chest, and so has individual seacocks for each of those 5 items.

Sea Spirit Yachts went further, putting seacocks on above-the-water-line drains, such as deck drains, as well as on the outlets from the air conditioner, water maker, and so on. Even in the event of a severe list (tilt) in the boat, it will be possible to choose which holes in the boat are open and which are closed.

Sea Spirit Yachts went further, putting seacocks on above-the-water-line drains, such as deck drains, as well as on the outlets from the air conditioner, water maker, and so on. Even in the event of a severe list (tilt) in the boat, it will be possible to choose which holes in the boat are open and which are closed.

Air Conditioning

Sea Spirit has a CruisAir “tempered water” system. Time will tell how well this system works, but it has some advantages over a system that blows cold air through the boat. The main advantage is that odors from one room don’t get blown into another room. However, CruisAir has a problem with their system. The inrush current when the compressors come on is very high. So high, that it started to cause momentary low voltage conditions on the boat, which caused the lights to flicker, and so on. The solution should have come via a free upgrade from CruisAir. However, we had to buy the upgrade, in the form of a pair of CruisAir “Smart Start” boxes. These control the compressors at start-up time, limiting the inrush current to something reasonable. Having installed these boxes, the problem has disappeared, and we are happy with the system. The CruisAir system has reverse cycle heat, and can be supplemented by a diesel boiler to further raise the temperature of the “tempered water”. With the boat in Florida, I thought I’d leave the installation of a diesel boiler until we were somewhere where the technicians see a lot of them, such as Seattle.

Get-home engine

The jury is still out on this one. Most single-engine commercial fishing boats have no backup engine at all. But to me, the idea of having a backup means of propulsion was very attractive. Sea Spirit has the Keypower Get Home drive. This is a hydraulic motor that clamps around the propellor shaft, and is bolted to the hull. It is driven by hydraulic power supplied from either or both of Sea Spirit’s generators. So, if the main engine stops turning the propellor shaft, it is possible to start one of the generators, flip a couple of switches in the wheelhouse (or engine room) and engage the get-home drive. The drive works in forward or reverse, and is fully proportional. However, like most auxiliary means of propulsion, it doesn’t make the boat go very fast. I need to do some more measurements, but I think 3 to 4 knots is all I’m going to get. That’s enough to keep the boat pointed in the right direction and making some headway, but if a failure happens a long way from land, it could take a long time to “get home”.

There are two alternatives to this approach. One is to have twin main engines instead of a single. The other is to have a “wing engine” mounted off to the side, with its own shaft and folding prop, much as a sailboat might have. Both of these approaches have one big advantage over Sea Spirit, and also some disadvantages. The advantage is this. if the reason the boat stopped moving is that the propellor became tangled, there is a possibility that the other engine’s prop is still free. But in return for that advantage, you either get a very cramped engine room (twins) or a wing engine that you have to keep exercised or else forget about it starting when you really need it. Even so, I have read a few accounts where people’s wing engines have become entangles by whatever entangled the main propellor. I’ve also read accounts where wing engine shafts became a significant source of seawater leaking into the boat. If I were one of those people who absolutely must have a wing engine with its own shaft (as opposed to twin engines, or an around-the-main-shaft system such as Sea Spirits), I would strongly consider having that wing shaft be driven hydraulically from a generator. That way, you get the extra drive shaft, but not the extra engine to worry about. Still, keeping it leak-free and in working order might make me wish for a system like Sea Spirit’s. In many respects, the compromise that Sea Spirit has is a very good one, but it is arguable as to whether it is the best one or not.

There was one thing I didn’t like about the get-home engine setup on Sea Spirit. The manufactuer had hidden the system’s controls underneath the helm, to be taken out only in the event of an emergency. I had the controls relocated to the main helm, where they will now be exercised frequently, since they are no longer “out of sight, out of mind”.

Fresh water pumps

Sea Spirit has twin HeadHunter fresh water pumps, both of which are plumbed in and ready to go. This is the ultimate form of “spare part”, although it does mean that both pumps need to be exercised from time to time. With a 400 gallon capacity, there should always be plenty of fresh water for wash downs, showers, and so on.

Watermaker

Sea Spirit did not come from the factory with a watermaker installed. This is understandable, since there is so much owner-preference for watermaker brands. I chose a Sea Recovery Aquamatic 1800 gallon per day system. But why would I want to make 1800 gallons per day? Simple, because that means I can make 75 gallons while running the generator for only one hour. The other 23 hours of the day can be quiet. The Aquamatic is fully controllable from the wheelhouse or from a panel on the unit itself. Also, the unit speaks “NMEA 2000” networking, meaning that I should be able to monitor and/or control it from an iPad sooner or later.

I chose to install a “modular” watermaker. This means that the various parts — filters, pumps, membranes, and so on — are separate from each other, and can be mounted wherever the shape of the boat best allows. In Sea Spirit’s case, the boat had a fair amount of space under the swim step, and that’s where much of the watermaker went. We paid particular attention to access, since we didn’t want to ruin the great job that Sea Spirit Yachts did in providing good access to pretty much everything on the boat. I don’t have any good photos of the system right now, but will modify this blog entry once I do.

Access panels

This is another area where Sea Spirit Yachts learned more as it built more and more hulls. Mine is hull #2, and while access was plentiful and generous, that access sometimes required unscrewing things. While it is inevitable that some things will require unscrewing, I am not comfortable with inspection items that require unscrewing. In Sea Spirit’s case, I felt there needed to be more easily removable (without screwdriver) access panels than there were. For example, there weren’t as many access panels in certain places, such as the engine room floor, where it would be useful to inspect bilges, sensors, and so on. Instead, whole floor panels needed to be unscrewed in order to access certain things that were operating below.

Sea Spirit Yachts has improved this situation on future hulls. But I wanted my hull to have the benefit of those lessons too. We worked with a fabricator to create access panels in the floor that could simply be lifted out. In my view, a panel that must be unscrewed is a panel that will not be unscrewed until too late. By contrast, a panel that can easily be lifted out will be inspected much more frequently, hopefully avoiding a problem, or at least detecting it while still in a convenient place and time. Here is an example of one of the new engine room floor access panels.

Similarly, there were a few places on the boat where I wanted to be able to quickly look at some components, but found them located behind screwed-in access panels. The answer: Replace those panels with easily-openable doors, hatches, and so on. There were only a handful of them, but having got this right, I now feel we can really easily and quickly check out anything on the boat. Here is a “before” example of one panel that I felt needed a better method of access, and that now has one.

House batteries

At least, that’s what I’m used to calling them in the motorhome world. I’m referring to the batteries that feed the inverter, lights, electronics, and so on. There are several other batteries on the boat, for starting the main engine, generators, dinghy, and so on. But the house batteries are important, because without them, you can’t have light or amenities without running a generator.

Sea Spirit has a 24 Volt electrical system, and came with 4 8D Lifeline AGM batteries. In my opinion, while these are wonderful batteries, there are not enough of them. Fortunately, there were 4 more identical batteries just sitting around doing almost nothing most of the time. These are the batteries for the bow and stern thruster. I had an electrician wire in a switched connection between the house and thruster banks, effectively doubling the amount of power available at anchor. For the techies among us, it goes like this. Before the change, I had about 10 kilowatt hours of battery capacity. After the change, I now have 20 kilowatts. It is always a good idea to discharge the batteries no more than 50% (perhaps a bit more for AGM batteries). This means that after the change, I can comfortably use 10 kilowatts overnight, or draw down about 416 Amp hours at 24 Volts (832 Amp hours at 12 Volts), and still not be drawing the batteries down by more than 50%. For comparison purposes, a 1500 Watt microwave on for 6 minutes uses about 6.25 Amp Hours at 24V.

Incidentally, there are various switches for interconnecting or isolating the banks of batteries on the boat. So, if I want to use the house batteries to boost the generator or main engine starting batteries, I can do so. Similarly, I can use any of the 4 alternators on the boat, or even the inverter and battery charger, to charge any and all of the battery banks. I hope never to need these interconnects, but they could come in handy in the event of a bad battery or an inattentive skipper. Here is an example of some switches for controlling the battery interconnects. In this case, these control whether the generator and main engine batteries are interconnected or not, and whether they are allowed to feed each of the two generators. In this case, they are.

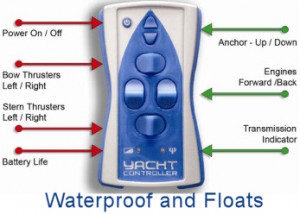

Engine controls and YachtController

This might be controversial. I have three sets of engine controls on the boat. One in the wheelhouse. One on the flybridge. And one in my pocket. The pocket one is called YachtController, and is essentially a radio frequency remote controller that runs the transmission, bow thruster, stern thruster, and anchor windlass. I nearly didn’t install a YachtController, opting instead for additional wired controls. But when I looked at where I wanted those controls, there was always just one more place. Portuguese bridge port and starboard, cockpit, back of the upper boat deck, near the anchor on the foredeck — it became ridiculous. I don’t know whether there will be problems with the YachtController, and there are things it won’t do, such as control the rudder or rev up the engines. It is most emphatically NOT as capable as full duplicated engine/rudder/thruster controls. But, it can be used anywhere on the boat. It can even be used to nudge a thruster from the dock, which we’ve all wished we can do from time to time when tying up short-handed.

I can see myself possibly adding another set of full engine controls at the stern if the YachtController is insufficient on poor to moderate days. But I am hoping it works out well.

Little bilge sumps for various things

The air conditioner condensation runs into its own small bilge box, about a foot across and a few inches deep. The shower sumps also run into something similar. Those boxes then feed either overboard or into a grey water tank. This strikes me as a great system, keeping two common sources of daily water out of the main bilges. In this picture, you can see the sump that collects air conditioner condensate. All those droplets are on the inside of the box, but are pumped overboard. If the pump ever fails, the sump would just overflow into the main bilge. But this way, those bilges remain dry in normal operation.

Engine room filtered bilge tank

There are a couple of sumps in the engine room where bilge water might accumulate. Since they are in the engine room, the bilge water may have some oily particles in it. Rather than pumping these overboard, they are sent through an oil/water separator, which looks like a large drinking water filter. From there, it passes into an 80 US gallon enclosed bilge tank. This tank can be pumped overboard or, can be pumped out at the dock. I believe this is an extremely environmentally friendly way to go, since it gives me the ability to clean up a messy, oily bilge, and either discharge overboard or (if it is really oily, say from a spilled oil bucket or blown hydraulic line), have it pumped out later. I have not seen this on any other boats, although I’m sure that just means I should take more engine room tours.

Charles Isoboost transformers

These are really cool. Well, not literally. Literally, they are fairly hot, at least when in use. What they are is transformers that automagically detect low shore power voltage, and increase it by 15%. When the shore voltage comes back up again, it automagically reverts back to unboosted operation. This protects the boat’s systems from many shore power problems. The Isoboost transformers also provide electrical isolation from shore power, and there are galvanic isolators too. Apparently, these transformers are particularly good at bringing 208V power up to 240V, allowing me greater flexibility in shore powering. I’m sorry the pictures don’t give you more of a sense of scale. The units are about a foot wide, and half as much again tall. When in heavy use, they get almost too hot to touch, but the manual says they are supposed to. From what I’ve heard, other similar solutions get even hotter.

Fore and aft power inlets

Sea Spirit has 50 Amp and 30 Amp power inlets both fore and aft. One of the aft ones is on a Glendinning electric cord retracter/extender, greatly lessening the chore of hooking up.

Side deck door

Between the side deck and the cockpit (at the back of the boat), there is a door that can be latched closed during windy days at sea. This leaves the rear area completely protected, even if there’s a 30 knot gale blowing across the bow. You can see the door on the starboard side in this photo of a sister ship (hull #3).

Boarding doors at different levels

It is possible to board Sea Spirit at three different levels: Swim platform near the water, starboard amidships 3 steps up from that level, and starboard foreward another couple of steps up again. This means that a great tidal variation can be accommodated, even with non-floating docks. I’ve seen many other boats where there is far less vertical variation in terms of ability to come aboard.

Electronics

This is mostly a good news story, although there are a couple of frustrations. Sea Spirit came with a trio of Garmin 5212 Chartplotters, Garmin radar, depth sounder, autopilot, and GPS, and an ICOM M604 VHF radio. While this certainly did the boat and crew proud while running around the boat shows on the East coast of the US, there were some missing items of importance to me for longer, offshore voyaging. In addition to the electronics mentioned above, I added the following: Garmin AIS, another M604 VHF radio, an ICOM M802 SSB radio, five Garmin GMI-10 displays (overkill, but hear me out), a KVH Mini-VSAT satellite Internet and telephone system, an Airmar PB-200 wind and atmospheric pressure sensor, an Airmar ultrasonic speed-through-the-water system (which I really bought to let the Garmin chart plotters compute current), and dedicated antennae for cellular and Wifi services. I also replaced the existing VHF antenna with a taller one. To top off the upgrades, I added a closed circuit television system so that I could monitor the engine room, cockpit, and boat deck from the helm, or from any convenient iPad/PC. Phew, this was the most major upgrade to the boat since buying it!

Why did I install 5 GMI-10 instrument displays? I put one in each cabin, so that whoever is sleeping there can open an eye and see what the wind/current is doing, which way the bow is pointed, and whether the anchor is dragging. This is an absolute luxury, but wasn’t very expensive to install. I also installed two GMI-10’s on the dash as “ancillary” displays for the helmsman.

So, what’s not to like? The ICOM radios won’t receive instructions from the Garmin chart plotters. If it were a Garmin radio, I could click on an AIS target on the chart plotter, and have my radio call that boat using its MMSI number. But since the ICOM doesn’t talk to the Garmin, if I want to do that I need to key in the other boat’s MMSI number by hand. No big deal, but this is the year 2011, and such things should just work. Ok, in the big scheme of things, this is a very minor thing to be annoyed about. But there are a few others. The Garmin chart plotters, which are superb pieces of equipment, apparently don’t have enough oomph to display video data at full screen resolution. So, from the helm, I can have a 1/4 screen window looking into the engine room, but cannot zoom it to full screen. This is unacceptable, as is the suggested solution from Garmin — to upgrade to 7212’s from 5212’s. The 7212’s don’t have this problem. But they are very expensive when bought in lots of three. Before committing to this upgrade, I am going to consider whether a different approach to chart plotters might be better, one involving personal computers and flat screen displays.

For now, even with these limitations, the Garmin 5212 chart plotters are still wonderful. They integrate a 2D or 3D view of the world, radar, XM weather, and instruments, and present it all with a touch screen interface that is fairly simple to use. And the rest of the system is absolutely phenomenal!

Wheelhouse

This was what made my wife fall in love with the interior of the boat (although she’s pretty mechanically inclined too). The notion of having the wheelhouse as a roomy gathering place for meals, home-schooling, or what-have-you, really appealed to us. There is a huge amount of space here — it is really another living room. It is also possible to close this room off from the salon/galley with a wooden door, allowing all sorts of things to be happening in the salon without disturbing the helmsman. This is particularly useful at night, where glare from a television or house lights could ruin the helmsman’s night vision.

Interior layout

I’m not going into any detail here. You can see the pictures on other parts of this web site, or on the manufacturer’s site. It suffices to say that Sea Spirit’s tastes and our own certainly coincide. There’s a lot of really nice wood here, all perfectly put together. We’ve always liked wood — we even used to live in a log cabin in Calgary.

Comments are closed.