Yet another delightful day of Sandinsanity! Managed to get the rest of the first coat of epoxy sanded. Tomorrow I’ll skip up on top and start coating the keel & bottom panels. Got a call out on Facebook for volunteer epoxy mixers. Offered beer &…

Archive | She:Kon RSS feed for this section

It’s all part of the learning curve

So you saw this pic yesterday.Freshly coated with tinted epoxy. Well apparently I should have squeegeed it out to get the lil’ air bubbles etc. out. Live and learn. So today I sanded the area with 80 grit on the RO and the Flexicats. It’s amazing how y…

Starting to seal ‘er up!

I had no idea what I was going to actually do this morning when I went out to the shed. I had tested some epoxy tint a couple of days ago and that seemed to go Ok so I mixed up some more and decided to go down one side.The camera had a hard time gettin…

Order from Chaos

I’ve got this whole boat flipping thing constantly on my brain. Was up half the night thinking about it and how I’ll get it done. Decided to break it down into little steps that all lead up to the big event (likely July 30th.).Step #1: Get my sh*…

Just a weeeeeeee bit of frustration

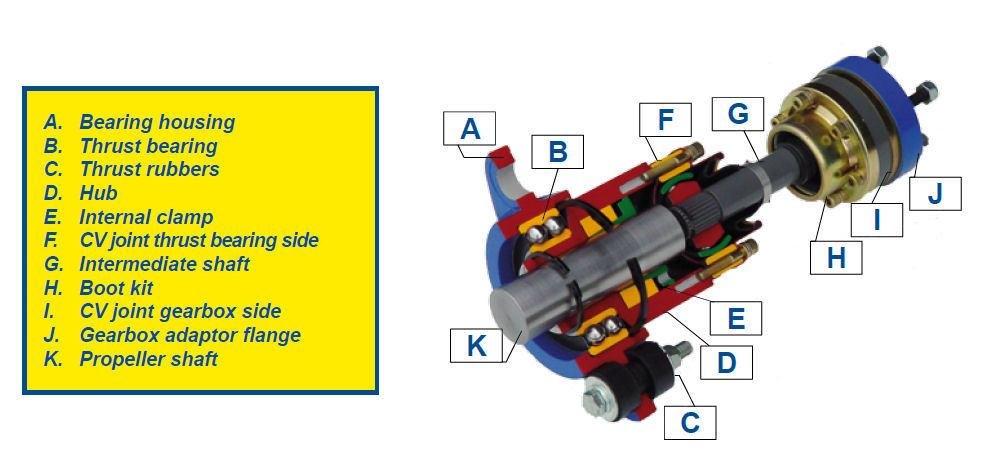

So, I wanted to get a custom intermediate shaft made for my Python Drive.

|

||

| Photo Credit: http://www.todddunnmicroyachts.com/tortuga/repower-2.html |

| Photo Credit: http://www.cruisersforum.com/forums/f54/installing-a-3jh4e-yanmar-rant-36940-2.html |

Shipping: €80 – $116.25

Shipping: €80 – $116.25

Bank surcharge: $30.00

EMT: $100.00

Total: €224.51 – $326.25 Cdn

Transfer Fee: $6.99

Payment Fee: $4.74

Delivery Fee: FREE

Total that you pay: $198.25 (Cdn)

This ain’t Pixar

This is no Pixar animation!  I’ve never done an animation before. It was really clunky to do in Sketchup (more likely ’cause I have no idea of what I’m doing) but I was trying to illustrate how I’ll use a Gin Pole to flip the hull over.I’ve om…

I’ve never done an animation before. It was really clunky to do in Sketchup (more likely ’cause I have no idea of what I’m doing) but I was trying to illustrate how I’ll use a Gin Pole to flip the hull over.I’ve om…

It may have been

a holiday for our friends south of the border but the work never stops in the Big Blue Boat Building Shed!  I put the kid (Thomas) through his paces for a few hours this morning sanding the keel and bottom panels.Here he is going down th…

I put the kid (Thomas) through his paces for a few hours this morning sanding the keel and bottom panels.Here he is going down th…

Quick update

Went out to the shed at 08:00 and it was already 85 degs in there! I knew I had to get some Quikfair on the keel so we can sand it tomorrow when the help arrives. I managed to get it done in about half an hour but I was soaked with sweat. It must have …

More hands make light work

A couple weeks ago I put an ad on some Facebook pages. It went something like this.”Do you have an able bodied teenager sitting in your basement playing video games all day and raiding your fridge? I have need of one to help me with a project.”I …

I just couldn’t do it

Just couldn’t get up ’nuff gumption to work on the boat today. I tried. Lasted about an hour and I was done. Maybe ’cause I know I got help coming tomorrow or maybe because it’s just hot outside, I dunno.One thing I did was start a blog for my bestest …