As you may see I’ve started an overhaul of the links on this blog, as all the old ones appeared dead. If you’d like a link to your own blog, or website or whatever, or if I’ve removed you and you’d like to be put back, please get in touch via the…

Archive | Wendy Ann 2 RSS feed for this section

Linkage.

As you may see I’ve started an overhaul of the links on this blog, as all the old ones appeared dead. If you’d like a link to your own blog, or website or whatever, or if I’ve removed you and you’d like to be put back, please get in touch via the…

Baggywrinkles.

Noun:

Protective covering made from old rope yarns wound around parts of a ships rigging to prevent chafe.

I am about to stretch the above metaphor possibly beyond usefulness. But left to my own devices and looking for something diverting to occupy me during xmas I hit upon the idea of doing something more or less pointless, fairly domestic and utterly distracting. I know, the gangplank is still fucked but shhh, never mind that for a minute.

The deckhead in our wheelhouse cabin has been unfinished plywood for some years, and inspired by Mark’s escapades wallpapering his kitchen with OS maps, Becky and I thought we were going to paper our ceiling in maps or charts. Discussions ensued regarding where these maps should represent, you choose, no, go on, you choose…Oh, who wants a map of bloody Lowestoft on their ceiling anyway. So without an accord the whole thing was ignored for a long time, and then for good measure we ignored it for a fair bit longer.

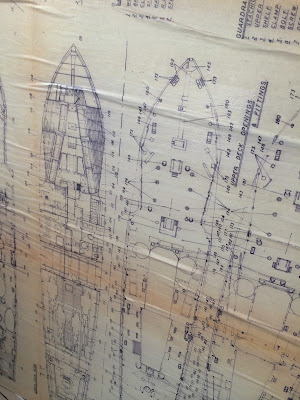

Whilst having a fight with a bookshelf two weeks before christmas, I found a large manilla envelope containing old blueprint positives that I’ve had since I was twelve years old. I was a fucking weird kid. And I had a thing for boats even then, or at least the idea of them, and looking over the drawings again I found myself just as pleased by their aesthetic complexity as when I was younger. How I’ve managed to hold on to them for so long is just one of life’s little mysteries I suppose.

The only problem was that there were not enough drawings to cover all nine panels on the deckhead. As we shall see, this led to a project-saving decision, completely by accident. I took the drawings to a well known branch of copy shop, luckily the man operating the machinery was a super geek type of guy, so was pleased to engage in a task that was well outside his normal duties. After some farting around with printer settings and a bit of swearing at the giant scanner whilst cleaning it I left the shop with a full set of A1 reproductions, plus the necessary couple of spares.

Back at the boat I mused on the how to of gluing it all down. I tuned in to YouTube for advice. Several videos involving crafty ‘merican ‘moms’ doing crafty stuff with crafty glue later I had two conflicting strands of advice. Essentially these were as follows: 1) keep everything dry, or 2) keep everything wet. The paper will swell up if it gets wet, and it will want to cause wrinkles.

I tested various methods on scraps of plywood and discovered that spraymount seems like a good idea, until the solvent in spray varnish dissolves it all and the paper just peels off on its own. Spraymount also has an interesting effect on cats who decide to try walking across the workspace. Then I tried sealing the paper with spray varnish, before gluing it down with watered down PVA. Disaster, even with paper at A4 size it curls over itself and sets immediately to form a sort of glued together cone of uselessness, attempts at preventing the curling action lead to wallpapering your own hands, and ending up with a crumpled ball of uselessness. I never even got it near the scrap of plywood..

Coming to the conclusion that ‘merican moms are full of shit I decided the only way for it was to embrace a wet gluing process. Tested it, got wrinkles, tested it again, got smears on the ink as I tried brushing it out. Decided I had run out of stuff to test on so it was time to throw caution to the wind and just go for it. Well. The first two small panels went ok. and dried flat enough. So I sealed the results with acrylic varnish and, lulled into a false sense of security attacked the first two big panels. In the morning they were dry, and really fucking wrinkly.

I went back to the copy shop for replacement reproductions.

Home again, the only thing I could think of was pre wetting the paper to persuade it to get the whole ‘I’m gonna expand ‘cos I’m wet’ thing over with, and then glue it down carefully before it turned to mush. Obviously this wasn’t going to work with a large sheet of paper flapping about. But noticing that the wrinkles always ran one way I decided that if the paper was rolled up along that direction I could wet, stretch and unroll, wet, stretch and unroll. I used a plant mister for the wetting bit.

So, the results look a bit ‘boys own’, and betray the onset of the New Year, there are several small wrinkles in the resulting ceiling covering. But I’m surprised at how little it really matters, and I’ve still got the originals. So if the sight of these imperfections ever starts to really chafe, I can always have another go.

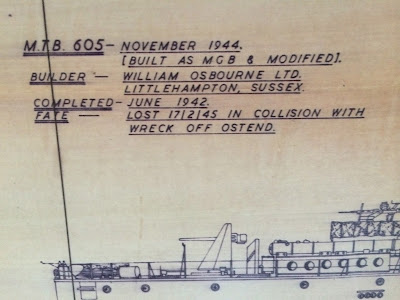

And here is a weird gem. One of the drawings shows examples of different types of the same vessel, and lists when and where they were built. Look at this. This one was built HERE. Wendy Ann 2 is moored at the old William Osborne’s boatyard in Littlehampton. And I didn’t even notice until I was putting the finished panel up.

Here’s to a New Year folks, I wish you a year of getting somewhere whatever direction you point yourself in. Even if this life is far from perfect at the best of times, we can only do the best we can in the time we’ve got, and I guess everyone has to live with a few baggywrinkles here and there. Let’s do it.

Baggywrinkles.

Noun:

Protective covering made from old rope yarns wound around parts of a ships rigging to prevent chafe.

I am about to stretch the above metaphor possibly beyond usefulness. But left to my own devices and looking for something diverting to occupy me during xmas I hit upon the idea of doing something more or less pointless, fairly domestic and utterly distracting. I know, the gangplank is still fucked but shhh, never mind that for a minute.

The deckhead in our wheelhouse cabin has been unfinished plywood for some years, and inspired by Mark’s escapades wallpapering his kitchen with OS maps, Becky and I thought we were going to paper our ceiling in maps or charts. Discussions ensued regarding where these maps should represent, you choose, no, go on, you choose…Oh, who wants a map of bloody Lowestoft on their ceiling anyway. So without an accord the whole thing was ignored for a long time, and then for good measure we ignored it for a fair bit longer.

Whilst having a fight with a bookshelf two weeks before christmas, I found a large manilla envelope containing old blueprint positives that I’ve had since I was twelve years old. I was a fucking weird kid. And I had a thing for boats even then, or at least the idea of them, and looking over the drawings again I found myself just as pleased by their aesthetic complexity as when I was younger. How I’ve managed to hold on to them for so long is just one of life’s little mysteries I suppose.

The only problem was that there were not enough drawings to cover all nine panels on the deckhead. As we shall see, this led to a project-saving decision, completely by accident. I took the drawings to a well known branch of copy shop, luckily the man operating the machinery was a super geek type of guy, so was pleased to engage in a task that was well outside his normal duties. After some farting around with printer settings and a bit of swearing at the giant scanner whilst cleaning it I left the shop with a full set of A1 reproductions, plus the necessary couple of spares.

Back at the boat I mused on the how to of gluing it all down. I tuned in to YouTube for advice. Several videos involving crafty ‘merican ‘moms’ doing crafty stuff with crafty glue later I had two conflicting strands of advice. Essentially these were as follows: 1) keep everything dry, or 2) keep everything wet. The paper will swell up if it gets wet, and it will want to cause wrinkles.

I tested various methods on scraps of plywood and discovered that spraymount seems like a good idea, until the solvent in spray varnish dissolves it all and the paper just peels off on its own. Spraymount also has an interesting effect on cats who decide to try walking across the workspace. Then I tried sealing the paper with spray varnish, before gluing it down with watered down PVA. Disaster, even with paper at A4 size it curls over itself and sets immediately to form a sort of glued together cone of uselessness, attempts at preventing the curling action lead to wallpapering your own hands, and ending up with a crumpled ball of uselessness. I never even got it near the scrap of plywood..

Coming to the conclusion that ‘merican moms are full of shit I decided the only way for it was to embrace a wet gluing process. Tested it, got wrinkles, tested it again, got smears on the ink as I tried brushing it out. Decided I had run out of stuff to test on so it was time to throw caution to the wind and just go for it. Well. The first two small panels went ok. and dried flat enough. So I sealed the results with acrylic varnish and, lulled into a false sense of security attacked the first two big panels. In the morning they were dry, and really fucking wrinkly.

I went back to the copy shop for replacement reproductions.

Home again, the only thing I could think of was pre wetting the paper to persuade it to get the whole ‘I’m gonna expand ‘cos I’m wet’ thing over with, and then glue it down carefully before it turned to mush. Obviously this wasn’t going to work with a large sheet of paper flapping about. But noticing that the wrinkles always ran one way I decided that if the paper was rolled up along that direction I could wet, stretch and unroll, wet, stretch and unroll. I used a plant mister for the wetting bit.

So, the results look a bit ‘boys own’, and betray the onset of the New Year, there are several small wrinkles in the resulting ceiling covering. But I’m surprised at how little it really matters, and I’ve still got the originals. So if the sight of these imperfections ever starts to really chafe, I can always have another go.

And here is a weird gem. One of the drawings shows examples of different types of the same vessel, and lists when and where they were built. Look at this. This one was built HERE. Wendy Ann 2 is moored at the old William Osborne’s boatyard in Littlehampton. And I didn’t even notice until I was putting the finished panel up.

Here’s to a New Year folks, I wish you a year of getting somewhere whatever direction you point yourself in. Even if this life is far from perfect at the best of times, we can only do the best we can in the time we’ve got, and I guess everyone has to live with a few baggywrinkles here and there. Let’s do it.

The Catfood Box Bomb.

If you look back at this blog to just before my long break you’ll see this is old news. But for one reader in particular , Chris in Sydney AU who is curious to know more, I thought I’d indulge.

Our primary heat source at home is the bigger of two woodburning stoves. The inspiring possibility that as a welder fabricator I could make my own is something I can blame squarely on my mum, she’d come to visit and had been staying with a friend who’d done something similar. And for a few weeks I turned the notion over in my head but didn’t really know where to go with it, searching the net for ideas only yielded the certainty that I didn’t want to make something out of an old gas bottle as that seemed a bit tame and the results still looked like the original thing no matter what.

We visited Becky’s parents for christmas and in the middle of the night on christmas eve I woke with a strangled yelp because the design I wanted had smacked me squarely in the brain, complete and ready to make. I fell out of bed and fumbled about in the dark for pen and paper, then gave up on the possibility of more sleep as I looked at the tiny sketch that I’d scribbled down. There it was, complete with the geared closure mechanism that now graces the doors. Several cups of coffee later I thought maybe a single door for the firebox would be easier than the gate I’d drawn but that was the only thing I changed from my half dreamed anvil dropped on head inspiration.

As documented already I built the shell of it at Becky’s stables. I gathered together one bottle of oxy, some propane, chalk and a full sheet of 1/2 inch plate and set to in the middle of the car park cutting and grinding and tacking the start of my weird vision made real. I think Becky’s customers thought I’d finally flipped but I was in my noisy, filthy steelworking element.

Then the owner of the yard dropped the apocalypse on Becky and her clients, He wanted to flatten the stables and build six luxury homes, because the south of england really needs more of them. She was served the minimum legal notice to clear out and give the bastard vacant possession.

I took a rented workshop up the road from our boat and started packing tools, when we forklifted the half built stove onto our trailer for transport I seriously thought it was going to squash it. I did a few back of envelope calculations and realised my little monster weighed approximately 300 kilos, and the trailer was legit for only 250. We pumped the tyres up a bit more and drove to the south coast as gingerly as possible, especially round the corners.

A few weeks later and installed in my new cavernous workshop I burned my way through two boxes of welding rods building up multiple passes as I welded the plates together, then ground the corners back to a nice radius and welded the top plate on.

The project waited patiently through the spring and summer while we found some work but with the arrival of autumn and the by now traditional sewing of selves into thermal underwear I tackled the project again. Did the geared mechanisms with help from local machinists who turned up the mounting bosses, ran into trouble welding the handles onto the cogs but discovered that cast iron welding rods did the trick. Ordered some stove glass and hefty firebricks and then made up a tee for the flue out of 150mm heavy wall pipe and hoisted the new stove onto a trolley, and towed it outside with the truck for testing. I attached a short length of flue and lit the stove. The resulting spectacle drew a bit of a crowd so consequently I got fuck all done the rest of the morning but everyone seemed to like it.

Getting the new stove on board turned into a whole project on its own. I originally considered delivery by boat at high water, this was how we got the generator on after all and that weighs in at just over half a ton. The weather however had other ideas, and one autumn gale after another swept through to stymie the suggestion. The alternative was delivery by land. Unfortunately our vessel is moored to a muddy island with uneven ground, access to which is via a narrow footpath and over a narrower footbridge. I measured everything and made a cup of tea.

I made my solution out of some scrap angle and some wheelbarrow wheels. After a few frantic hours I’d built a sort of heavy duty barrow that we could strap the stove onto, and it was specifically made to JUST fit the footbridge. It was not a thing of beauty but I fervently hoped it would do. To address the awkward problem of lifting my lump on board I made a sheerleg out of 75mm box, this was essentially a giant A frame, and I hoped that with two chainhoists it would function as a crane.

Living on boat rule number 347: chainhoists are your friend.

Part one of the big move was undertaken by Becks and myself. We hoisted the stove onto its dolly and strapped it down hard, luckily we got the balance more or less right and trundled off down the road with it attracting funny looks from the local ramblers. navigating the footbridge went slowly, left a bit right, keep that wheel on that line and over we went the longer flatter way round the island and next to the boat. I attached the sheerleg hook and was ready to lift. We decided to leave the trolley attached as the hoist took the weight just in case anything went wrong, and as I pulled the chains the new stove rose, as planned into the air. Then my banksman ran away. Becky was wibbling about on the other side of the island shouting that the sight of it all made her armpits itch. I coaxed her back and once the trolley was off we swung three hundred kilos of steel on deck just so. Then we both ran away to the pub.

Part two of the move involved Jan and me, my best lifting and slinging buddy. The next morning off came the engine room skylight and by means of rollers, chainhoists and davits we lifted the stove along the deck, up and across and then down into the middle of the engine room floor. Rearranged the hoists for one more lift forward a couple of metres onto the hearth and remarkably into the right place first time. It took the rest of the day to rearrange the flue sections and fire-cement everything together.

Ever since then the stove has supplied us with a plentiful and reliable heat source. One day I will get around to plumbing in the boiler back that I built into it, but for now it works great as a simple stove, happily eating whatever fuel we throw into it. One day soon I’d love to build another one.

So, why the Catfood Box Bomb of the title?

That’s easy. My preferred method of lighting our stove goes like this: Take one empty catfood box, fill with scrunched newspaper and curls of woodshavings. surround with wigwam of wood splints, cedar is brilliant, but this utile stuff is surprisingly good too and thats a hardwood. Apply lit match. Close door, open vents. After a few minutes, stoke her up and you’re all set for a nice warm evening.

The Catfood Box Bomb.

If you look back at this blog to just before my long break you’ll see this is old news. But for one reader in particular , Chris in Sydney AU who is curious to know more, I thought I’d indulge.

Our primary heat source at home is the bigger of two woodburning stoves. The inspiring possibility that as a welder fabricator I could make my own is something I can blame squarely on my mum, she’d come to visit and had been staying with a friend who’d done something similar. And for a few weeks I turned the notion over in my head but didn’t really know where to go with it, searching the net for ideas only yielded the certainty that I didn’t want to make something out of an old gas bottle as that seemed a bit tame and the results still looked like the original thing no matter what.

We visited Becky’s parents for christmas and in the middle of the night on christmas eve I woke with a strangled yelp because the design I wanted had smacked me squarely in the brain, complete and ready to make. I fell out of bed and fumbled about in the dark for pen and paper, then gave up on the possibility of more sleep as I looked at the tiny sketch that I’d scribbled down. There it was, complete with the geared closure mechanism that now graces the doors. Several cups of coffee later I thought maybe a single door for the firebox would be easier than the gate I’d drawn but that was the only thing I changed from my half dreamed anvil dropped on head inspiration.

As documented already I built the shell of it at Becky’s stables. I gathered together one bottle of oxy, some propane, chalk and a full sheet of 1/2 inch plate and set to in the middle of the car park cutting and grinding and tacking the start of my weird vision made real. I think Becky’s customers thought I’d finally flipped but I was in my noisy, filthy steelworking element.

Then the owner of the yard dropped the apocalypse on Becky and her clients, He wanted to flatten the stables and build six luxury homes, because the south of england really needs more of them. She was served the minimum legal notice to clear out and give the bastard vacant possession.

I took a rented workshop up the road from our boat and started packing tools, when we forklifted the half built stove onto our trailer for transport I seriously thought it was going to squash it. I did a few back of envelope calculations and realised my little monster weighed approximately 300 kilos, and the trailer was legit for only 250. We pumped the tyres up a bit more and drove to the south coast as gingerly as possible, especially round the corners.

A few weeks later and installed in my new cavernous workshop I burned my way through two boxes of welding rods building up multiple passes as I welded the plates together, then ground the corners back to a nice radius and welded the top plate on.

The project waited patiently through the spring and summer while we found some work but with the arrival of autumn and the by now traditional sewing of selves into thermal underwear I tackled the project again. Did the geared mechanisms with help from local machinists who turned up the mounting bosses, ran into trouble welding the handles onto the cogs but discovered that cast iron welding rods did the trick. Ordered some stove glass and hefty firebricks and then made up a tee for the flue out of 150mm heavy wall pipe and hoisted the new stove onto a trolley, and towed it outside with the truck for testing. I attached a short length of flue and lit the stove. The resulting spectacle drew a bit of a crowd so consequently I got fuck all done the rest of the morning but everyone seemed to like it.

Getting the new stove on board turned into a whole project on its own. I originally considered delivery by boat at high water, this was how we got the generator on after all and that weighs in at just over half a ton. The weather however had other ideas, and one autumn gale after another swept through to stymie the suggestion. The alternative was delivery by land. Unfortunately our vessel is moored to a muddy island with uneven ground, access to which is via a narrow footpath and over a narrower footbridge. I measured everything and made a cup of tea.

I made my solution out of some scrap angle and some wheelbarrow wheels. After a few frantic hours I’d built a sort of heavy duty barrow that we could strap the stove onto, and it was specifically made to JUST fit the footbridge. It was not a thing of beauty but I fervently hoped it would do. To address the awkward problem of lifting my lump on board I made a sheerleg out of 75mm box, this was essentially a giant A frame, and I hoped that with two chainhoists it would function as a crane.

Living on boat rule number 347: chainhoists are your friend.

Part one of the big move was undertaken by Becks and myself. We hoisted the stove onto its dolly and strapped it down hard, luckily we got the balance more or less right and trundled off down the road with it attracting funny looks from the local ramblers. navigating the footbridge went slowly, left a bit right, keep that wheel on that line and over we went the longer flatter way round the island and next to the boat. I attached the sheerleg hook and was ready to lift. We decided to leave the trolley attached as the hoist took the weight just in case anything went wrong, and as I pulled the chains the new stove rose, as planned into the air. Then my banksman ran away. Becky was wibbling about on the other side of the island shouting that the sight of it all made her armpits itch. I coaxed her back and once the trolley was off we swung three hundred kilos of steel on deck just so. Then we both ran away to the pub.

Part two of the move involved Jan and me, my best lifting and slinging buddy. The next morning off came the engine room skylight and by means of rollers, chainhoists and davits we lifted the stove along the deck, up and across and then down into the middle of the engine room floor. Rearranged the hoists for one more lift forward a couple of metres onto the hearth and remarkably into the right place first time. It took the rest of the day to rearrange the flue sections and fire-cement everything together.

Ever since then the stove has supplied us with a plentiful and reliable heat source. One day I will get around to plumbing in the boiler back that I built into it, but for now it works great as a simple stove, happily eating whatever fuel we throw into it. One day soon I’d love to build another one.

So, why the Catfood Box Bomb of the title?

That’s easy. My preferred method of lighting our stove goes like this: Take one empty catfood box, fill with scrunched newspaper and curls of woodshavings. surround with wigwam of wood splints, cedar is brilliant, but this utile stuff is surprisingly good too and thats a hardwood. Apply lit match. Close door, open vents. After a few minutes, stoke her up and you’re all set for a nice warm evening.

Joining The 21st Century, The Hard Way.

Warning: at some points this article may become excessively technical. Don’t worry, I haven’t a clue what I’m doing either, but it’s surprising how much we can learn given the right kind of need. I’d say don’t try this at home, but I just did and I’m still not dead. I guess it depends on how bonkers your domestic arrangements are.

We’ve survived the last few years on board with what I believe is termed a ‘rats nest’ of extension cables and whilst the 12 volt side of things has gradually come together to provide a reasonably coherent system that powers lighting, pumps and soundsystem power/phone charging via what we’ve always termed My-First-Inverter (a cheap device from maplin), the big power from our generator has always been assumed too dangerous and mysterious to play with so we’d run extensions along the deck every time we needed juice.

My old skipper Alan says POWER IS EVERYTHING, so with that in mind here is a little story of how far we’ve come.

Back at the beginning of this year and feeling unexpectedly flush I purchased a fancypants bit of technology, an inverter/charger that promised to deliver real, pure sine wave 220v AC power. the motivation was to power the computer on which I’m typing right now. The My-First-Inverter that we’ve had for years produces a simplified version of AC power, essentially just switching power back and forth 50 times a second (Hertz) and when we tried plugging the computer into it we noticed a disturbing and loud buzzing sound coming from inside; we decided that really didn’t sound too good so we switched it off. Ever since then the computer has only run when the generator was running, reducing its role more or less to writing invoices for work. This would not do forever.

I proudly screwed the new super inverter to the side of our battery compartment and cheerfully wired up the 12v side of things using the most monstrous cables I’ve ever seen, thicker than my thumb, but that was all I thought I could do. I had several longing examinations of consumer units (fuse boards for want of a better description) and was completely baffled so we decided we needed someone who knew what they were doing, an actual electrician. Our work promised a favour that at some point one would visit and help us wire everything up.

Over the course of a few weekends Becky and I ran all the cables that would supply sockets around the home as well as the immersion heater and electric side of the oven. Under floors and through bulkheads, practising a kind of gonzo contortionism to thread the cables through. Going behind the port side water tank I couldn’t reach the cable end that Beck was waggling about for love nor money, so after a moment of head scratching I gaffer taped a spaghetti serving spoon to a stick for extending my reach and sort of snared the cable with it. Every electrician should have a spaghetti spoon in their toolbox, right?

Then we waited, but all the electricians at work were busy, running around daft busy. We were bumped to the bottom of the list.

One night in early summer the generator shut itself down unexpectedly, and I was horrified to discover an empty fuel tank, smoke pouring off the engine top and fuel dripping from all over the deckhead. I needed engineering advice, and after many questions directed at Damian, Wolfy and Robin I discovered the fuel lines leaked like sieves. No wonder the generator had been a bugger to start as at rest the lines were filling themselves up with air. The final straw that caused the rather dramatic leak was a large split that opened up in the line north of the fuel injector pump. I learned about bleeding air, non return fuel valves and the fact that I now required a third hand and a flip top neck to do up new hose clamps around the injectors themselves. I replaced the entire fuel line system from one end to the other and suddenly the generator would start straight away every time. Result.

I got all excitable about the possibility of making the generator ‘remote start’. Up until this point I’d have to go on deck, open a hatch, climb into the generator room and turn a key to make it go. We wanted to start the thing from the domestic side of our vessel. Robin drew me a circuit diagram and helped me learn all about the wonder of relay switches. These clever little devices enable a low power circuit, one that can work over a long run of cable, activate a high power circuit- like a starter motor. I did all the work myself, even sussing out a second relay was going to be needed for the engine preheat circuit and the sense of fist pumping triumph when I turned a key in our galley at the other end of the boat from the generator and heard an engine vrummm distantly to life was worth all the head frying lessons on it’s own.

We waited a lot longer for an electrician. They were busier than ever.

Just over a week ago the long wait was over, and Kevin arrived to wire up two consumer units, one direct from the generator, and one south of the inverter/charger. I sploshed back and forth through a wellington booted high tide to the merchants for missing parts and extra pieces, and I helped provide earth bonding for each unit by fixing a hefty copper cable to frames of the hull.

Our big moment arrived and we ran up the generator to test the circuits.

First inklings that things were not quite as they should be came with the socket tester telling us we had an earth continuity fault. ‘Never mind’ says Kevin ‘that might be ‘cos we’re on a boat, let us test the inverter’. I read the instructions one more time for luck and switched it on in the order I was told to. Second inkling of trouble came with the discovery that whilst it would happily invert power up from the batteries the promised automatic switch over to charging just would not happen.

So I rang Sterling Power, the device’s manufacturer. I was told in no uncertain terms that the generator was the likely culprit. What technical support actually said was ‘your waveform is crap phone up the manufacturer and get them to supply you with a better voltage regulator’. O-kayy then, but I bought the generator second hand five years ago. When I got off the phone Kevin hit me with the third and final inkling of bad shit. While I’d been trying to keep up with Sterling Power he’d been testing the supply, ‘The power looks like its coming out backwards and theres a massive earth leak’ said Kevin, ‘did I wire that control box up the right way?’ he said ‘oh, yes, I did.’ he said. He explained that generators were outside his field of experience, so I thanked him profusely for his work and helped him load his van. I was on my own.

Except, I wasn’t. There were knowledgeable people I could telephone and bug for advice, again.

So it’s more learning time, again. With masses of help from Robin, Barry at Maple Electrics, Kevin, Alan at BP Norse Marine, and Meccalte UK technical support, and slightly less help from the internet which is confusing as hell; I have embarked on my journey to understand AC power. Think of it as a sort of crash course in AC electrics and electromechanical engineering. I only tried this because well, you try finding a generator expert the week before sodding christmas.

The journey began with the how to of multimeters, and getting my head round the idea that why on earth is power coming mostly from the neutral wire.

I took the cover off the alternator, and gazed at the mass of dirty copper. Right. More tests. That one is live, so is that one a bit, but not the other one. And I don’t know what this one does. The simplest answer is that whoever sold me the generator in the first place had wired it up the wrong way round. Ok, swap that wire for this wire. Next, earth leak. Could it be dirt and filth? I cleaned the rotor and stator up as best I could with Jizer. Oooh look at all those lovely diodes. I considered complete dismantling of alternator, baulked. Put it back together. Two hours later, same ‘earth leak’ but the other way around. Next the discovery that while the frequency was about right the voltage was under 200v. So I made another couple of phone calls and after assuring the manufacturers that whilst I was no electrician I was prepared to give any advice sensible consideration a method of increasing voltage while leaving frequency in the same place was revealed. The alternators output is transformer controlled. The transformer is that row of three copper sausages on top of the output stator. Its core is made of two iron forms, one is E shaped, and next to it is one that is I shaped. There is a TINY air gap between the two. Undoing all the nuts and carefully increasing that gap should increase the voltage. I do not know why. But I took the thing apart, cleaning as I went and after a few hours managed to wedge that gap open a bit. Reassemble again. Ran the bugger up and a moment of pure celebration when tests revealed 236VAC at 50Hz bang on. Put the generator under heavy load and that figure drops to 220VAC at 50Hz. Acceptable according to advice and it looks like I’ve successfully sorted two big issues.

I’m still a way to go. The ‘earth leak’ may not be an earth leak at all. many older generators are non polarity specific, I’m told this means that voltage is measured across live to neutral, therefore output is the total of voltage measured live to earth (vessel) and neutral to earth. Somebody mentioned earth bonding neutral to earth as a possibility. I gave this a go and decided it was a bad idea when I got a bit of a zap, the sort that makes your teeth rattle, the generator made a terrible clunking sound while I convulsed so I guess that’s not a sensible solution, and understandably I’m reluctant to repeat the experiment live to earth.

So, all reassembled and running various things are working. One thing is not. Good news items are: No more extension leads, anywhere. This here computer runs fine on the new inverter, with no scary wasps nest within sounds. The immersion heater heats a tank of water quicker than it did. And the electric side of the range works for the first time ever.

Bad news item is: The sodding inverter STILL won’t flip over to charging. The received wisdom is that this is a sensitive piece of electronics and it is therefore extremely picky about the kind of power input it likes. Bollocks. One thing I somewhat unsurprisingly don’t own is an oscilloscope, a device that would help me to see the waveform depicted graphically. I am however not quite done yet, and apparently an old style 50 watt light bulb may help stabilise the waveform although I’m buggered if I know why. Another possibility is purchasing a thing called a voltage regulator, which purportedly may help to scrub the waveform up. This will need to be wired in just north of the offending inverter.

Of course, complete dismantling and cleaning of the alternator is still a reluctant possibility too, but since it appears to at least mostly work this will be reserved for last ditch engineering attempts.

Are any readers still with me? If you’ve made this far A) well done, and B) there is a distinct likelihood that you have become confused. Congratulations and welcome to the club because I am too. But I shan’t be beaten mostly because I’m definitely still not dead and I regard this as a bonus of sorts.

After coming so far the internet bit was easy. I just phoned up the mobile phone company and bought one of these fancy mobile wifi thingies. At least this appears to work without taking it to bits over and over again.

In an effort to celebrate things mostly functioning, last night we slammed some food in the oven and curled up to watch the silliest DVD we could find on the computer. It was brilliant.

Joining The 21st Century, The Hard Way.

Warning: at some points this article may become excessively technical. Don’t worry, I haven’t a clue what I’m doing either, but it’s surprising how much we can learn given the right kind of need. I’d say don’t try this at home, but I just did and I’m still not dead. I guess it depends on how bonkers your domestic arrangements are.

We’ve survived the last few years on board with what I believe is termed a ‘rats nest’ of extension cables and whilst the 12 volt side of things has gradually come together to provide a reasonably coherent system that powers lighting, pumps and soundsystem power/phone charging via what we’ve always termed My-First-Inverter (a cheap device from maplin), the big power from our generator has always been assumed too dangerous and mysterious to play with so we’d run extensions along the deck every time we needed juice.

My old skipper Alan says POWER IS EVERYTHING, so with that in mind here is a little story of how far we’ve come.

Back at the beginning of this year and feeling unexpectedly flush I purchased a fancypants bit of technology, an inverter/charger that promised to deliver real, pure sine wave 220v AC power. the motivation was to power the computer on which I’m typing right now. The My-First-Inverter that we’ve had for years produces a simplified version of AC power, essentially just switching power back and forth 50 times a second (Hertz) and when we tried plugging the computer into it we noticed a disturbing and loud buzzing sound coming from inside; we decided that really didn’t sound too good so we switched it off. Ever since then the computer has only run when the generator was running, reducing its role more or less to writing invoices for work. This would not do forever.

I proudly screwed the new super inverter to the side of our battery compartment and cheerfully wired up the 12v side of things using the most monstrous cables I’ve ever seen, thicker than my thumb, but that was all I thought I could do. I had several longing examinations of consumer units (fuse boards for want of a better description) and was completely baffled so we decided we needed someone who knew what they were doing, an actual electrician. Our work promised a favour that at some point one would visit and help us wire everything up.

Over the course of a few weekends Becky and I ran all the cables that would supply sockets around the home as well as the immersion heater and electric side of the oven. Under floors and through bulkheads, practising a kind of gonzo contortionism to thread the cables through. Going behind the port side water tank I couldn’t reach the cable end that Beck was waggling about for love nor money, so after a moment of head scratching I gaffer taped a spaghetti serving spoon to a stick for extending my reach and sort of snared the cable with it. Every electrician should have a spaghetti spoon in their toolbox, right?

Then we waited, but all the electricians at work were busy, running around daft busy. We were bumped to the bottom of the list.

One night in early summer the generator shut itself down unexpectedly, and I was horrified to discover an empty fuel tank, smoke pouring off the engine top and fuel dripping from all over the deckhead. I needed engineering advice, and after many questions directed at Damian, Wolfy and Robin I discovered the fuel lines leaked like sieves. No wonder the generator had been a bugger to start as at rest the lines were filling themselves up with air. The final straw that caused the rather dramatic leak was a large split that opened up in the line north of the fuel injector pump. I learned about bleeding air, non return fuel valves and the fact that I now required a third hand and a flip top neck to do up new hose clamps around the injectors themselves. I replaced the entire fuel line system from one end to the other and suddenly the generator would start straight away every time. Result.

I got all excitable about the possibility of making the generator ‘remote start’. Up until this point I’d have to go on deck, open a hatch, climb into the generator room and turn a key to make it go. We wanted to start the thing from the domestic side of our vessel. Robin drew me a circuit diagram and helped me learn all about the wonder of relay switches. These clever little devices enable a low power circuit, one that can work over a long run of cable, activate a high power circuit- like a starter motor. I did all the work myself, even sussing out a second relay was going to be needed for the engine preheat circuit and the sense of fist pumping triumph when I turned a key in our galley at the other end of the boat from the generator and heard an engine vrummm distantly to life was worth all the head frying lessons on it’s own.

We waited a lot longer for an electrician. They were busier than ever.

Just over a week ago the long wait was over, and Kevin arrived to wire up two consumer units, one direct from the generator, and one south of the inverter/charger. I sploshed back and forth through a wellington booted high tide to the merchants for missing parts and extra pieces, and I helped provide earth bonding for each unit by fixing a hefty copper cable to frames of the hull.

Our big moment arrived and we ran up the generator to test the circuits.

First inklings that things were not quite as they should be came with the socket tester telling us we had an earth continuity fault. ‘Never mind’ says Kevin ‘that might be ‘cos we’re on a boat, let us test the inverter’. I read the instructions one more time for luck and switched it on in the order I was told to. Second inkling of trouble came with the discovery that whilst it would happily invert power up from the batteries the promised automatic switch over to charging just would not happen.

So I rang Sterling Power, the device’s manufacturer. I was told in no uncertain terms that the generator was the likely culprit. What technical support actually said was ‘your waveform is crap phone up the manufacturer and get them to supply you with a better voltage regulator’. O-kayy then, but I bought the generator second hand five years ago. When I got off the phone Kevin hit me with the third and final inkling of bad shit. While I’d been trying to keep up with Sterling Power he’d been testing the supply, ‘The power looks like its coming out backwards and theres a massive earth leak’ said Kevin, ‘did I wire that control box up the right way?’ he said ‘oh, yes, I did.’ he said. He explained that generators were outside his field of experience, so I thanked him profusely for his work and helped him load his van. I was on my own.

Except, I wasn’t. There were knowledgeable people I could telephone and bug for advice, again.

So it’s more learning time, again. With masses of help from Robin, Barry at Maple Electrics, Kevin, Alan at BP Norse Marine, and Meccalte UK technical support, and slightly less help from the internet which is confusing as hell; I have embarked on my journey to understand AC power. Think of it as a sort of crash course in AC electrics and electromechanical engineering. I only tried this because well, you try finding a generator expert the week before sodding christmas.

The journey began with the how to of multimeters, and getting my head round the idea that why on earth is power coming mostly from the neutral wire.

I took the cover off the alternator, and gazed at the mass of dirty copper. Right. More tests. That one is live, so is that one a bit, but not the other one. And I don’t know what this one does. The simplest answer is that whoever sold me the generator in the first place had wired it up the wrong way round. Ok, swap that wire for this wire. Next, earth leak. Could it be dirt and filth? I cleaned the rotor and stator up as best I could with Jizer. Oooh look at all those lovely diodes. I considered complete dismantling of alternator, baulked. Put it back together. Two hours later, same ‘earth leak’ but the other way around. Next the discovery that while the frequency was about right the voltage was under 200v. So I made another couple of phone calls and after assuring the manufacturers that whilst I was no electrician I was prepared to give any advice sensible consideration a method of increasing voltage while leaving frequency in the same place was revealed. The alternators output is transformer controlled. The transformer is that row of three copper sausages on top of the output stator. Its core is made of two iron forms, one is E shaped, and next to it is one that is I shaped. There is a TINY air gap between the two. Undoing all the nuts and carefully increasing that gap should increase the voltage. I do not know why. But I took the thing apart, cleaning as I went and after a few hours managed to wedge that gap open a bit. Reassemble again. Ran the bugger up and a moment of pure celebration when tests revealed 236VAC at 50Hz bang on. Put the generator under heavy load and that figure drops to 220VAC at 50Hz. Acceptable according to advice and it looks like I’ve successfully sorted two big issues.

I’m still a way to go. The ‘earth leak’ may not be an earth leak at all. many older generators are non polarity specific, I’m told this means that voltage is measured across live to neutral, therefore output is the total of voltage measured live to earth (vessel) and neutral to earth. Somebody mentioned earth bonding neutral to earth as a possibility. I gave this a go and decided it was a bad idea when I got a bit of a zap, the sort that makes your teeth rattle, the generator made a terrible clunking sound while I convulsed so I guess that’s not a sensible solution, and understandably I’m reluctant to repeat the experiment live to earth.

So, all reassembled and running various things are working. One thing is not. Good news items are: No more extension leads, anywhere. This here computer runs fine on the new inverter, with no scary wasps nest within sounds. The immersion heater heats a tank of water quicker than it did. And the electric side of the range works for the first time ever.

Bad news item is: The sodding inverter STILL won’t flip over to charging. The received wisdom is that this is a sensitive piece of electronics and it is therefore extremely picky about the kind of power input it likes. Bollocks. One thing I somewhat unsurprisingly don’t own is an oscilloscope, a device that would help me to see the waveform depicted graphically. I am however not quite done yet, and apparently an old style 50 watt light bulb may help stabilise the waveform although I’m buggered if I know why. Another possibility is purchasing a thing called a voltage regulator, which purportedly may help to scrub the waveform up. This will need to be wired in just north of the offending inverter.

Of course, complete dismantling and cleaning of the alternator is still a reluctant possibility too, but since it appears to at least mostly work this will be reserved for last ditch engineering attempts.

Are any readers still with me? If you’ve made this far A) well done, and B) there is a distinct likelihood that you have become confused. Congratulations and welcome to the club because I am too. But I shan’t be beaten mostly because I’m definitely still not dead and I regard this as a bonus of sorts.

After coming so far the internet bit was easy. I just phoned up the mobile phone company and bought one of these fancy mobile wifi thingies. At least this appears to work without taking it to bits over and over again.

In an effort to celebrate things mostly functioning, last night we slammed some food in the oven and curled up to watch the silliest DVD we could find on the computer. It was brilliant.

Broken Things part 1.

Here’s a picture of our gangplank, which this week is vying with the toilet for top spot on the chart of really annoying broken stuff. Funnily enough I’m quite happy to live with a broken toilet, at least we have a temporary alternative. When I say ‘quite happy’ I actually mean am able to tolerate. The alternative to this load of bollocks can be seen on the top right of the picture. Yes, we are tight-roping our way across the chasm of certain mud every day on two 6×2” planks, loosely bound together with a couple of second hand screws. What a shambles. As if that weren’t fun enough it has suddenly turned very frosty indeed so walking the planks has become shall we say um, a little exhilarating in the mornings.

As you can see from the picture I was so disgruntled at storm Angus’ handiwork that I’ve just abandoned the wreckage where it landed. In my defence it is/was quite heavy, but it has to go as it’s bringing down the tone of the neighborhood and attracting the wrong sort of crowd.

Obviously I’ve got to fix this, and before too long. The two planks near-death-experience arrangement will not survive the next spring tides without near constant mothering, so that’s less than a week. Oh goody.

This was Thing 2 of gangplank/staging construction, and somewhere waaay back in this blog I’ve written about making it in the first place. I don’t know if you remember but Thing 1 was completely total rubbish and just floated away on a surprise tide when I wasn’t looking. This one was never really meant to be a long term thing, cobbled together out of scrap timber so I’m amazed it’s survived something daft like five years.

But its all over bar the bonfire now, I suppose the wager is, in three weeks time will Seb and Becky still be tottering across this deeply unsatisfactory arrangement? Will either of us have fallen in, and if so how many times? And to what extent will I have managed to have begun construction of an adequate replacement?

Broken Things part 1.

Here’s a picture of our gangplank, which this week is vying with the toilet for top spot on the chart of really annoying broken stuff. Funnily enough I’m quite happy to live with a broken toilet, at least we have a temporary alternative. When I say ‘quite happy’ I actually mean am able to tolerate. The alternative to this load of bollocks can be seen on the top right of the picture. Yes, we are tight-roping our way across the chasm of certain mud every day on two 6×2” planks, loosely bound together with a couple of second hand screws. What a shambles. As if that weren’t fun enough it has suddenly turned very frosty indeed so walking the planks has become shall we say um, a little exhilarating in the mornings.

As you can see from the picture I was so disgruntled at storm Angus’ handiwork that I’ve just abandoned the wreckage where it landed. In my defence it is/was quite heavy, but it has to go as it’s bringing down the tone of the neighborhood and attracting the wrong sort of crowd.

Obviously I’ve got to fix this, and before too long. The two planks near-death-experience arrangement will not survive the next spring tides without near constant mothering, so that’s less than a week. Oh goody.

This was Thing 2 of gangplank/staging construction, and somewhere waaay back in this blog I’ve written about making it in the first place. I don’t know if you remember but Thing 1 was completely total rubbish and just floated away on a surprise tide when I wasn’t looking. This one was never really meant to be a long term thing, cobbled together out of scrap timber so I’m amazed it’s survived something daft like five years.

But its all over bar the bonfire now, I suppose the wager is, in three weeks time will Seb and Becky still be tottering across this deeply unsatisfactory arrangement? Will either of us have fallen in, and if so how many times? And to what extent will I have managed to have begun construction of an adequate replacement?